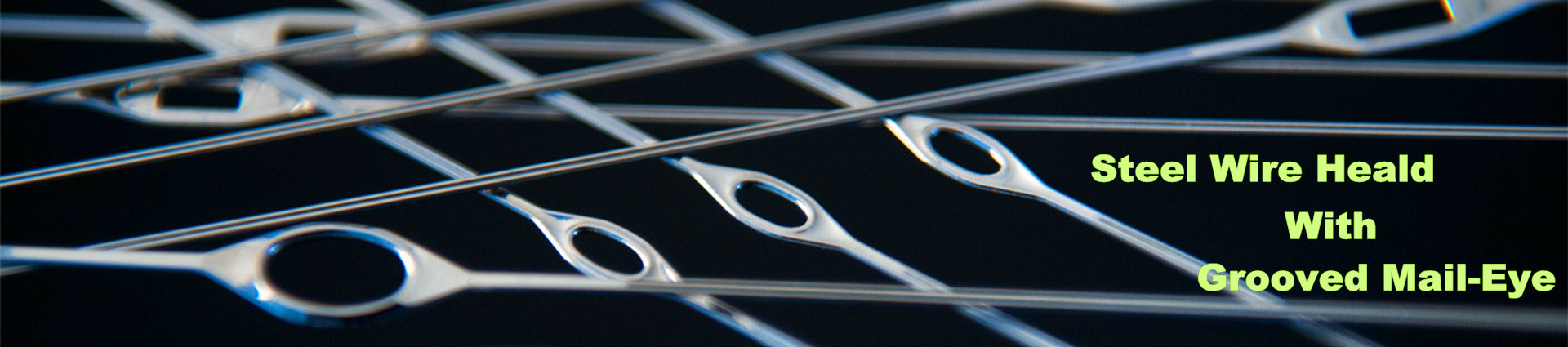

- Textile Accessories

- Shuttle Loom Parts

- Textile Equipment

- 1511 Textile Machine Parts

- 1515 Textile Machine Parts

- GA615 Shuttle Loom Parts

- Textile Hardware And Tools

- Weaving Machinery

- Textile Auxiliary Equipment

- Textile Picker and Buffer

- Textile Wooden Parts

Analysis Of Cloud Weaving Or Segmented Weaving Faults On 1515 Loom

The semi active warp feeding mechanism of the 1515 series loom often causes warp feeding imbalance due to improper installation or wear and looseness of the components during operation, resulting in weaving defects such as cloud weaving (uneven and sparse fabric surface) and segmental weaving. Loom Repair, Cloud Weaving, Segment Weaving, Weaving Machine Malfunction, Loom Maintenance,The following is a detailed fault analysis:

I. Mechanical failure causing cloud weaving or segmented weaving

The spring (B61D) of the saw gear brake disc has low elasticity, and the brake disc is worn or oil stained with felt (R38), causing the saw gear to rotate flexibly and resulting in segmental weaving defects.

Improper mesh tightness between the feed worm gear (3428) and the feed worm gear (B19) can cause abnormal feed or wear; The umbrella gear cover (B78S) collided with the umbrella gear, causing intermittent delivery, resulting in mechanical failure and cloud weaving.

The warp support feet (3432B, 3433B) are not properly installed, and the teeth of the warp disc (B7Y) and the feed gear (3429) cannot mesh properly. The transmission is tight and loose, which is also a cause of cloud weaving or segmented weaving.

The tension fan-shaped rod (3411A) or fan-shaped brake (C11Y) is worn or detached with leather (R11, R12), causing the tension fan-shaped rod to swing up and down violently, resulting in excessive fluctuations in warp tension.

Poor meshing of the feed wheel system and severe wear and tear, accumulation of flying flowers on the feed saw gears, affecting the movement of the support head (B23-25) and causing severe wear and tear on the support head.

The warp feeding side shaft (3426) and warp feeding shaft (3427) are deformed or not installed properly, resulting in sluggish rotation, sometimes fast and sometimes slow, causing segmented weaving.

The fastening screws of the warp support foot (B10) are loose, and the warp support foot pressure plates (B67, B68C) are not tightened or lost, causing the weaving shaft to jump and changing the meshing relationship between the warp disk teeth and the feed gear, resulting in cloud weaving phenomenon.

II. Mechanical failures and fabric and fabric appearance

The interaction between the brake lever pulley (C16Y) and the crankshaft cam (3211B) is not properly adjusted, which affects the function of the warp tension adjustment device, causing fluctuations in warp tension and changes in fabric width.

The tension rod is not active, the sensing system is not sensitive, and the fluctuation of warp tension cannot be adjusted in a timely manner, causing changes in the finished fabric width.

The height of the rear beam does not meet the requirements of the fabric process, which affects the appearance of the fabric.

The uneven height of the rear pole support feet (3400-5, 3400-6) causes the rear beam to tilt, resulting in uneven tension of the warp yarns on the left and right sides, which affects the uniformity of the fabric surface.

III. Mechanical failure and abnormal delivery

The adjustment rod (3416), friction serrated wheel support rod (B22), or warp feeding adjustment rod guide foot (C15) are severely worn out, and the up and down swing of the adjustment rod is obstructed, causing the self-adjusting function of the warp tension adjustment system to lose balance, resulting in warp feeding abnormalities and even breaking the adjustment rod guide foot.

Loose warp discs, loose gears and missing pins in the warp feeding mechanism, resulting in abnormal warp feeding.

The loosening of the heavy hammer (B65) of the warp feeding adjustment rod can cause the adjustment rod to lose control, the loosening of the warp feeding adjustment rod guide foot (C15), and the detachment of the adjustment rod, which can also cause abnormal operation of the warp feeding mechanism.